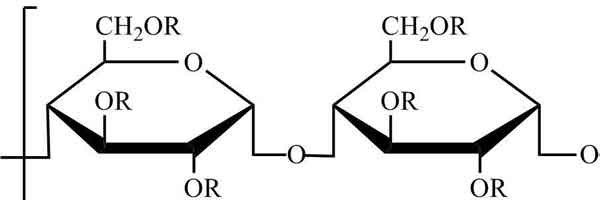

HPS (Hydroxypropyl Starch Ether)

| Packing | 25KG each, custom packing available |

| Delivery | Around 7 Days |

| Payment Terms | T/T or L/C at sight |

Catagories

Product Description

Specification

| Product Specification | |

| Appearance: | white or off-white |

| Moisture: | ≤5% |

| Ash: | ≤5% |

| Etherification(MS/DS): | 0.8-1.2/1.8-2.0 |

| pH value: | 6-8 |

| Gel temperature: | 70-85°C |

| Viscosity: | 1,000-75,000 mPa.s (Brookfield RV, 2%) |

HPS Applications

- Food industry, used as thickener, suspending agent and adhesive.

- In the paper industry, it is used as the internal and surface sizing of paper to make the printing ink bright and uniform, the glue film smooth, reduce the ink consumption, and have a certain roughening ability.

- In the textile industry, it is used as warp size to improve the abrasion resistance and weaving efficiency during weaving. Hydroxypropyl starch with high degree of substitution can be used as printing paste.

- Pharmaceutical industry, used as tablet disintegrating agent and plasma increaser.

- Oil drilling, stabilizing well wall, improving borehole conditions, anti sloughing, flocculating drilling cuttings, etc.

- Daily chemical industry, used as adhesive, suspending agent and thickener.

- In the food industry, it is used as adhesive, thickener and suspending agent to increase stability.

- Building materials industry, all kinds of (cement, gypsum, lime calcium based) internal and external wall putty; Various finishing mortar plastering mortar, All kinds of gypsum, ceramics and porcelain products are used as molding adhesives with low ash and good viscosity; It has good thickening and stability, and plays the role of suspension and emulsification in aqueous solution.

HPS Features

- Provide very good rapid thickening capacity; Medium viscosity, high water retention;

- The dosage is small, and a very low filling amount can achieve a very high effect;

- It can be used with methyl cellulose (MC) or hydroxypropyl methyl cellulose (HPMC) to reduce the use of cellulose ether:

- Improve the overall anti sag ability of the material, so that the material will not flow down (slide) when smearing or pasting other materials;

- It has good lubricity, which can improve the operating performance of the material and make the operation smoother.

Recommend Models

SN301:

Due to its unique chemical structure, GD301 can effectively prevent the phenomenon of flow hanging in thick layer mortar. It has an excellent improvement effect on the slipping of pasted tiles and the flow hanging phenomenon of thick layer plaster. SN301 can prevent the phenomenon of layering and segregation of mortar, and increase the wrapping property of sand and cement. SN301 has a rapid thickening effect and can improve the rheological properties of mortar products such as sprayed mortar and plastering mortar.

Adding an appropriate amount of GD301 to the mortar can prolong the open time of the mortar, and its water retention property can remain stable as the temperature rises. A small amount of GD301 can achieve a good effect, improve the operability of the material, and make it easy to apply.

SN406:

SN406 is a newly developed starch ether for gypsum-based products, especially suitable for the emerging lightweight plaster gypsum in the market. Based on the high substitution of lightweight propylene glycol ether starch, it greatly improves the resistance to sagging and flow hanging, and endows the system with good construction performance. It also improves the pumpability under mechanical spraying conditions. In addition, it addresses the issue of short setting time of gypsum-based products by adding a retarding effect.

Packaging and Delivery